10 Basic Principles Of KAIZEN

You can always improve yourself. Whether it is learning something new or perfecting a skill you already have, there is opportunity to get better in everybody’s life.See how every principles of Kaizen applied to one’s PERSONAL LIFE for continuous improvement.

1. Never Stop

There is an area for improvement in everyone’s life, no matter how successful they are. The idea here is to focus on continuous improvements in your life, every day, no matter how small the step you take to be a better you than you were yesterday.

2. Be Proactive

Stop hesitating because of possible hurdles that you predict, and move forward toward your goal for continuous improvement. It is important to not take any chance in the way of improvement, and for each person in the organization to take personal responsibility for making improvements. While it is one thing to sit around and discuss about the improvements that should be made, it is different thing to actually make an action plan to implement the changes.

3. Eliminate Old Practices

The main part of avoiding complacency is getting rid of old and tired traditions that are obsolete. Because we live in a culture that continually making changes and improvements, it is important for businesses to keep up with this in order to stay relevant for company’s continuous improvement . To get rid of old practices throughout your life, find out about step up your day by improving upon things that you already do. Let go of your former habits, even if they give you some benefit at the time. As time goes, you should progress also.

4. Don’t Stop

Never consider yourself to be finished. Improvement has no limits, and can be proceeded on an infinite level. You can always improve yourself. Whether it is learning something new useful things or perfecting a skill you already have, there is opportunity to get better in everybody’s life for continuous improvement.

5. Make Corrections

Some Part of the trial-and-error process requires making corrections to practices or processes that have a major issue with them. It is critical to continue to make corrections all through the process in order to continuous improvement. To Start some new habits to correct the things that you may have been doing wrong up until this point. Observe the areas in your life that can use improvement, and make relevant changes to help you progress.

6. Empower All Employees to Speak Up

Everyone who is associated in the success of the company—from the CEO to the line workers—should be encouraged to offer suggestions and solutions for problems that can be fixed, or improvements that can be made. While you don’t have employees dealing with your own life, you can still energize your friends and family to make suggestions if they see things that you could work on. Talk with different people about your goals and get their feedback. Encourage your family and friends to make suggestions if they see things that you could work on.

7. Don’t Assume New Methods Will Work

Just because a method is new does not mean that it is improved. It is main things to move far beyond the status quo in order to be effective in business. This will probably require trial and error until achievement is accomplished. When it comes to your personal life, it might take some time to find a method that works for you when it comes to achieving your goals. Just Because something worked for another person does not imply that it will essentially work for you. Try a few things out before you focus to a new method.

8. Practice the “Five Why” Method

Before making any final decisions, get to the root of the problem by asking “why?” five times. By continuing to ask yourself “why?” you are likely to find the genuine purpose behind a problem. Often, the assumed reason for a problem will actually lead to another question and dig deeper into the issue. possibly you have been telling yourself that you don’t have time to work out, and that is the reason you are out of shape.

9. Be Economical

Watch your finances during the entire process of making an improvement. Look for ways to save money while making minor improvements, and then spend the saved money on further improvements. A common goal of improvement is to save money or stop spending so much money on unuseful Things. And stop buying them.

10. Crowdsource

Learn from other people and get some new opinions on things you can add to your routine to create continuous improvement. Before making a change or improvement, Talk with different people about what they are doing in their daily life to improve themselves. You will learn from different people and get some new opinions on things you can add to your routine to create continuous improvement. Having multiple opinions can not only add to an improvement, but it may also offer a different perspective that will open up more new ideas.

I hope this kaizen principle will help you improve your organisation waste. Start implementing these world-class kaizen principles and get substantial improvement

“Try to do something just a little bit better each day in order to make a large impact in the long run”

Greendot Management Solutions

Greendot Management Solutions

- SMART Goal Setting in Six SigmaSMART Goal Setting in Six Sigma A SMART goal is an acronym that stands for Specific, Measurable, Achievable, Realistic, and Time-bound. Thus, SMART goals integrate all of these criteria to help us increase the possibilities of achieving your goal. The project’s goals and objectives can be defined base on the project scope and problem statement. Goal Statement defines the expected improvement […]

- 12 Step of TPM Implementation12 Step of TPM Implementation| How to Implement TPM? Few Things we will cover in this post of 12 steps of TPM implementation How to Apply TPM (Total Productive Maintenance)? Preface of TPM 8 Pillars of Total Productive Maintenance Benefits of TPM (Total Productive Maintenance) 12 steps of TPM Implementation Also watch TPM Video:- https://www.youtube.com/watch?v=M-YccQYqRr4&t=22s […]

- Muda Mura MuriWhat’s Muda Mura Muri in Lean Manufacturing? The 3M methodology in Lean Manufacturing is basically used in the Toyota Production System. The 3M stands for Muda, Mura, and Muri. This is a Japanese Concept. The goal of Lean Manufacturing is to deliver increased value to the client with the help of barring all kinds of wastes from […]

- 7 Types of Abnormalities in TPM7 Types of Abnormalities in TPM Anything which isn’t normal that’s called an abnormality Fuguai is a Japanese word. Fuguai means abnormality. We can also say that the abnormality is a deviation from the standard requirement. The abnormality is a very much popular concept in Total Productive Maintenance (TPM). Several types of abnormalities are the part of Jishu Hozen Pillar in TPM Abnormality classify Matrix is also prepared in JH […]

- 8 Wastes of Lean ManufacturingWhat are the 8 Wastes of Lean? 8 Wastes of Lean are identified as Transportation, Inventory, Motion, Waiting, Overproduction, Over-processing, Defects, & Skillset or Non-utilized talent. Earlier it was considered as 7 waste of lean manufacturing too. We will cover the following topics in this blog The acronym we can say is TIMWOODS or DOWNTIME. What’s Waste in Process or Lean Manufacturing? […]

- Cost of Quality vs Cost of Poor Quality (COPQ)What’s the Cost of Poor Quality (COPQ)? It’s the cost related to providing poor quality products or services. In easy words, we can say that it’s the total financial losses incurred by the company due to doing the wrong things. COPQ is the cost that would disappear if in smooth operating conditions. It’s a refinement of the conception of COQ. […]

- What is Lean Six Sigma ?What’s Lean Six Sigma? Sigma (𝝈) is the Greek letter representing a statistical unit of measure that defines the standard deviation (SD) of a population. Six refers to the number of SD’s from the technical limit to the mean. It measures the variability or spread of the data. 6 sigma is a largely structured strategy. […]

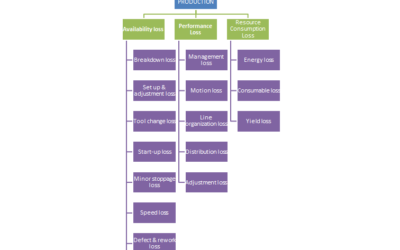

- Six Big Losses in OEESix Big Losses in OEE and TPM The Six Big Losses are responsible for productivity. We’ve to exclude these to ameliorate productivity. One of the major goals of TPM ( Total Productive Maintenance) and OEE (Overall Equipment Effectiveness) is to reduce and eliminate Six Big Losses. Also refer to: https://www.youtube.com/watch?v=6ubu3vO1LDs&t=70s OR https://www.youtube.com/watch?v=M-YccQYqRr4 We will cover the following topics in this blog Classification of Big Losses Classification of Six Big Losses in […]

- Top Lean ToolsTop lean Manufacturing – Lean Operation Tools Top lean Tools are the methodical and scientific approaches for problem- working. Spare Tools are also used for relating and barring waste from the system or process. These tools are veritably important to apply Lean Manufacturing culture in the plant. Watch video on lean manufacturing crash Course just […]

- 5S in the Workplace | 5S ImplementationWhat’s 5S in the Work Place? 5S Methodology was developed in Japan and it’s a system for organizing spaces so work can be performed efficiently & effectively safely and it’s a fundamental tool of Lean Manufacturing It’s a system for organizing space so work can be performed efficiently & effectively with safely. Now and then it’s also […]